In need of product assistance? Contact Opulent support

In the COVID-19 era there’s an acceleration of dental laboratory technicians and dentists combining forces to build in-house or in practice laboratories.Dental Consultants have been asked the same questions repeatedly, how do I set up a dental laboratory? What equipment should I buy? Who should I buy the equipment from? Do I need a laboratory technician?

This is the first part of four articles that will cover this topic. Part 1 is “Modeless In-House Laboratory”, Part 2 is “Traditional Models with Digital In-House Laboratory”, Part 3 is “Modeless & Models with Digital In-House Laboratory” and the final, Part 4 is “Adding Removables to your In-House Laboratory”

In this section we will be covering Part 1 “Modeless In-House Laboratory” which is to produce restorations without a traditional physical impression. The advantage of producing restorations in this manner is that it is quicker and more cost effective than pouring up a traditional model. The downside is that for some cases having a traditional impression/model is needed for fit and contacts verification. To properly scan a model you will need a Desktop Model Scanner which we will cover in Part 2 “Traditional Models with Digital In-House Laboratory”.

Why not purchase one of the “Same-Day” milling machines on the market today? Well, If you’re going to build an in-house laboratory then you will need more than Cerec, E4D or any other block only milling machine can offer. These mills are good for same-day dentistry, but the industry and technology has evolved from what these machines can offer. Furthermore, the technology is continuing to evolve so it is best to purchase a system that will grow with the technology through updates.

The reality is that laboratory equipment is more cost effective than the “clinical” machines that are offered to dentists. However, there is a lot of equipment and software to choose from on the laboratory side of dentistry. So we are going to help you navigate the laboratory terrain and help you make the correct decision. So here it is:

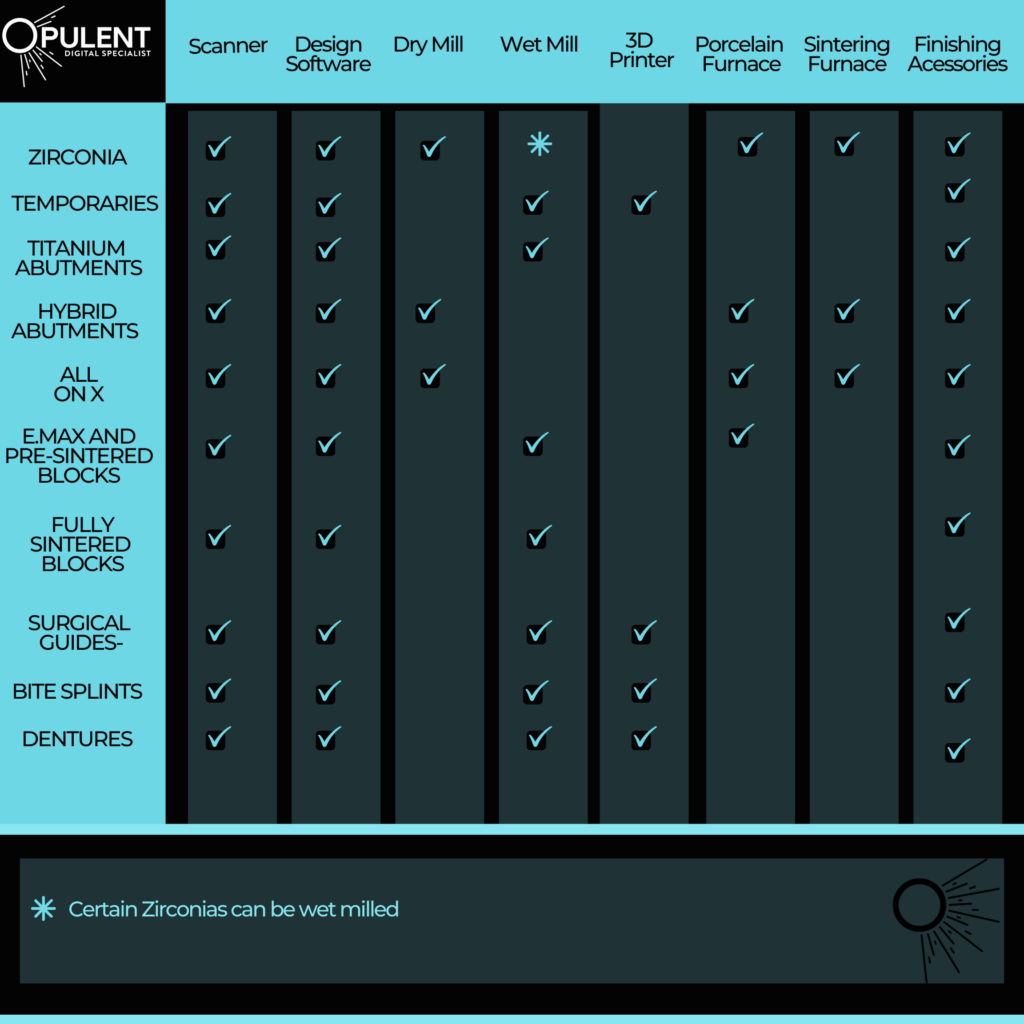

1. What do you want to produce? The type of restorations you want to produce in-house will dictate the type of software and equipment you need. Below is a list of each type of product that can be produced with CAD/CAM and what is needed to produce.

2. Should I hire a laboratory technician? Hiring a technician is optimal because they already know what the finished product should look like and the steps needed to achieve it. A technician is also valuable at the finishing stages of the process. However, if you choose to not hire a technician you can still achieve great results with a dental assistant or dentist doing the whole process. But, you need to understand that there will be a learning curve that you will need to embrace and be comfortable with, patience is the key to success.We have seen many dentists who have been successful without a technician.

3. What Intraoral Scanner should I purchase? The Intraoral Scanner market is becoming increasingly complicated by the day. This is because of new scanners being introduced and old scanners being upgraded with new technology and pricing. The Institute of Digital Dentistry did an excellent job of breaking down the current scanners on the market and listing the pros and cons of each. Although the report is from IDS 2019 not much has changed since the report due to COVID. Some important factors you should consider before purchasing are as follows:

4. What design software should I choose? The top two design softwares on the market are 3Shape and Exocad. Both softwares are open STL format and can communicate with all milling machines that you should be considering. Exocad has several re-branded versions available and all, except the Zirkonzahn version, are completely open. Furthermore, Exocad now offers a “Flex” license and “Bundle” packages to help reduce the cost of the end user. Both 3Shape and Exocad have annual fees associated with the software, however the Exocad Perpetual option does not require an annual fee for use of the software. Only the Exocad Flex and 3Shape require an annual fee to use the software.

3Shape and Exocad offer clinical software for the dentists but if you are considering a milling machine in this article the clinical software will not be robust enough for your needs. Either way, 3Shape of Exocad will cost you anywhere from $3,000 to $13,000 depending on the configuration purchased. One of these two softwares should be purchased.

5. What milling machine should I choose? First, lineup your restorations wish-list to the product capability of each machine. Next, the milling machine you choose should be an open system so you can receive files from 3Shape or Exocad. Furthermore the milling machine should be open to receive all materials. For Zirconia, PMMA and Wax this means the milling machine should have a 98mm holder which is standard in the US. Block material from GC, VITA, Ivoclar and others will use a “Universal” or “Cerec” style holder. With these holders you will be able to mill the majority of the products on the market. Also, the milling machine manufacturer should have a track record in the dental laboratory industry, because there are a lot of manufacturers who are new. Below is a list of manufacturers we suggest in order of recommendation:

In addition to product versatility the maintenance is minimal and switching between products is a 1-2 minute process. Amann Girrbach also offers the Matik Production Unit for 24 hour production, the Mikro 5X for dry only Zirconia or Wax 5-Axis Production and the Mikro IC 4-axis wet only, single to three-unit milling machine for E.max, Ceramic/Composite Blocks and Titanium Abutment production. Amann Girrbach milling machines are open systems and use their own CAM software. The best advantage with Amann Girrbach is they provide every aspect of the workflow, the CAD, CAM, Mill, Furnace, Finishing, Zirconia, Tools and accessories. So you support contacts will be minimal.

For wet/dry 5-axis milling VHF’s answer is the R5 which can do single units to full arch. This machine can mill Zirconia, PMMA, WAX, E.Max, Ceramic/Composite Blocks, Titanium Abutments and has add-ons for Full Dentures and Partial Denture Frameworks. In addition to product versatility the R5 has a 10 Blank disc holder to allow for continuous use. The price for these milling machines are a little higher than Amann Girrbach and there are less of the Z4 and R5 in use in the US. So, they are less tested on the US market. VHF uses its own CAM software and is an open system.

The reason why they do this is to save on cost and separate wet and dry milling. But, the combined cost does not save you money so it is more of a perception than a reality. Plus, Roland does not mill Titanium Abutments. Regardless, the Roland brand is considered to be a more dependable brand over other mills in the industry not named in this list. The DWX-52D and DCi require a third-party CAM software and the DWX-42DCi uses Rolands CAM software or a third-party software.

Second, there are some mills that are very high quality but they need a laboratory technician or engineer to operate. Again the machines mentioned above do not require this. Last, there are a lot of cheaper milling machines from overseas that promise a lot. These mills are a risk because they have not been thoroughly tested in the clinical market, so more than likely you will be left to figure out a lot of problems on your own.

Here is a guide to help you select what product needs wet milling, dry milling and printing:

6. What sintering furnaces do I need? You will need two types of furnaces in a digital in-house set up. First, you need a Zirconia Sintering Furnace for sintering zirconia. Second you will need a porcelain furnace for E.max processing, Porcelain Sintering and Stain/Glazing. If you do not plan on using E.max then you can get a Zirconia Furnace that has a Stain/Glaze cycle. If you do not plan on using Zirconia then get a porcelain furnace only. Zirconia Furnaces are $8,000 to $20,000 and Porcelain are $3,000 to $8,000. Best is to buy your furnaces from the same distributor you purchase your milling machine from as it will limit your support contacts if something goes wrong. Most Zirconia Furnaces require 220V connection.

7. Should I purchase a printer? Printers are great for cases that need model and contact verification. Also, you can print surgical guides, splints, custom trays, dentures and more with a printer. If you do not purchase at first you can purchase later as a majority of cases can be processed modeless. Nextdent, Sprintray, Asiga and Envisiontec all offer great printing options at an affordable price. The price range is $6,000 to $25,000 depending on the set up and if you purchase a post-curing unit and resin mixer.

8. What should I purchase? Below is a list of smaller items you should purchase for your system.

9. How much should I spend? To get a full system with the products we mentioned you will be spending $70,000 to $110,000 depending on the configuration. This range includes the Intraoral Scanner, without a Scanner the range is $50,000 to $90,000 depending on the configuration.

We have seen many different types of workflows in many types of settings. There have been laboratories set up in garages and living rooms. Whatever your needs are, it can be accomplished.

Hopefully this has helped you! If you have any questions feel free to reach out to me at jesse@opulentcadcam.com. Thank you

Enter your email for Our Digital Dentistry Newsletter & promotions.