In need of product assistance? Contact Opulent support

Match the Best In-House Equipment to the Best Support.

No payments for six months

Error: Contact form not found.

Amann Girrbach Matik Production System

Full Amann Girrbach Digital Show Presentation Link

The Ceramill Motion 2 is a benchmark in terms of the range of indications and materials in-house. The 5-axis milling unit combines wet and dry processing in one unit and enables the value-creation chain to be kept virtually completely in-house in the laboratory.

The Ceramill Motion 2 can be used either as a purely dry or wet unit or in combined operation for an unlimited range of materials and indications.

Amann Girrbach Ceramill Motion 3

The Ceramill Motion 3 is designed for wet and dry operation. The 5-axis milling machine operates completely autonomously and can therefore manufacture unsupervised both during the night or also on weekends when connected to the AG-Live platform. Users have the possibility of accessing the intelligent hybrid machine remotely, to receive orders safely and quickly, as well as to monitor everything related to production and customer service. And above all, the integrated analysis functions allow workflows in the laboratory to be analyzed and optimized on an ongoing basis.

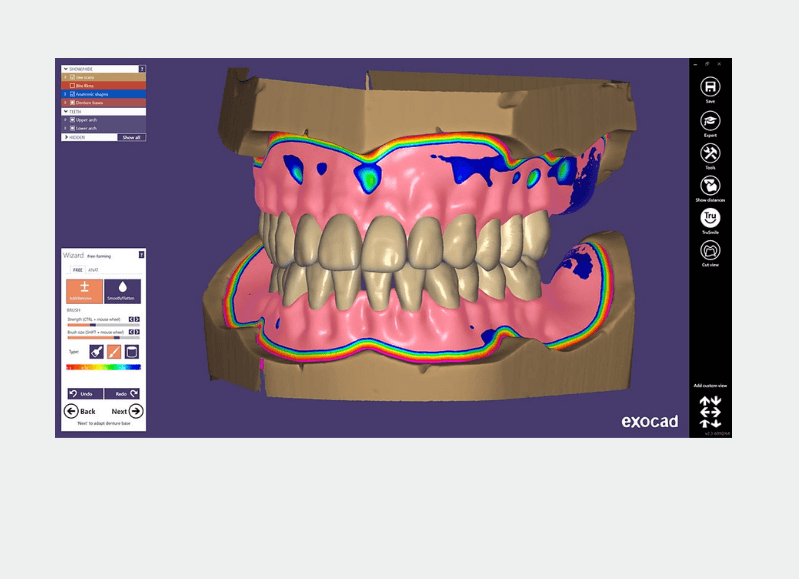

The Ceramill Mind design software, developed by Amann Girrbach in close collaboration with dental technicians, meets all requirements. Perfectly coordinated to the Ceramill Map scanner Ceramill Mind has been seamlessly integrated in the system architecture of the Ceramill system and is characterised by easy handling, process reliability and precision. The user guidance of the CAD programme, orientated to the standard laboratory workflow, greatly simplifies the framework fabrication process and covers an extensive range of indications from crown and bridge to complex implant restorations or full-denture prosthetics. Features and areas of application are progressively refined, allowing the Ceramill Mind to be upgraded by a large number of software modules.

Design, implant planning, orthodontics, production and scanning – the complete software solution for digital dentistry.

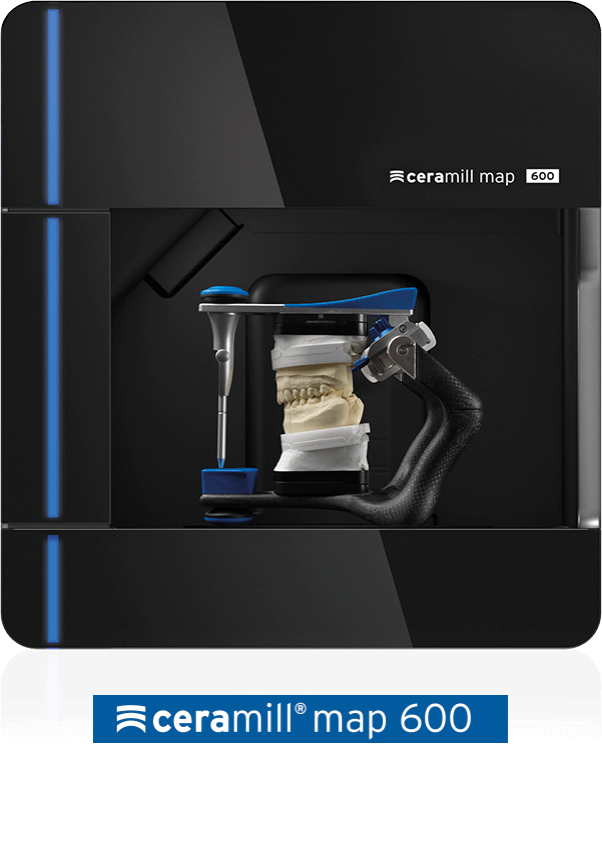

Who is this for?

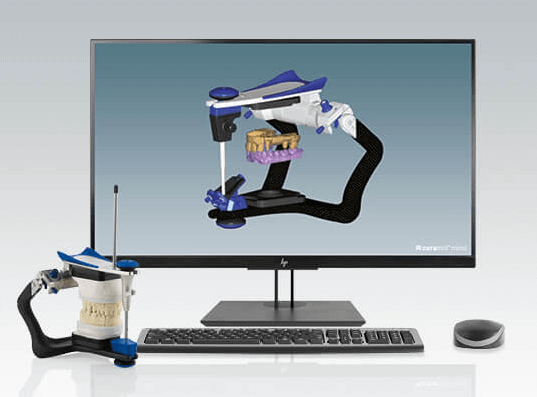

The fully automatic high-performance scanner for open articulator scanning. The new Ceramill Map 600 high-performance scanner from the DNA generation offers intelligence, efficiency and maximum precision. The scanner features an integrated universal carrier plate for all common types of articulator, which saves time-consuming plate changes. Due to Splitex integration, all the accessory components of the Map portfolio can be used. The intelligent scan height control automatically moves the object to be scanned into the best possible scan area, thus offering the user increased process reliability, maximum convenience and protection against incorrect use. The new drive technology with an automatic Z-axis ensures ultra-precise and fast travel movement. The highly sensitive industrial 3D sensor with Blue Light technology ensures outstanding depth of field and a scanning accuracy of 4μm.

The Ceramill Map 600 generates open STL or PLY data.

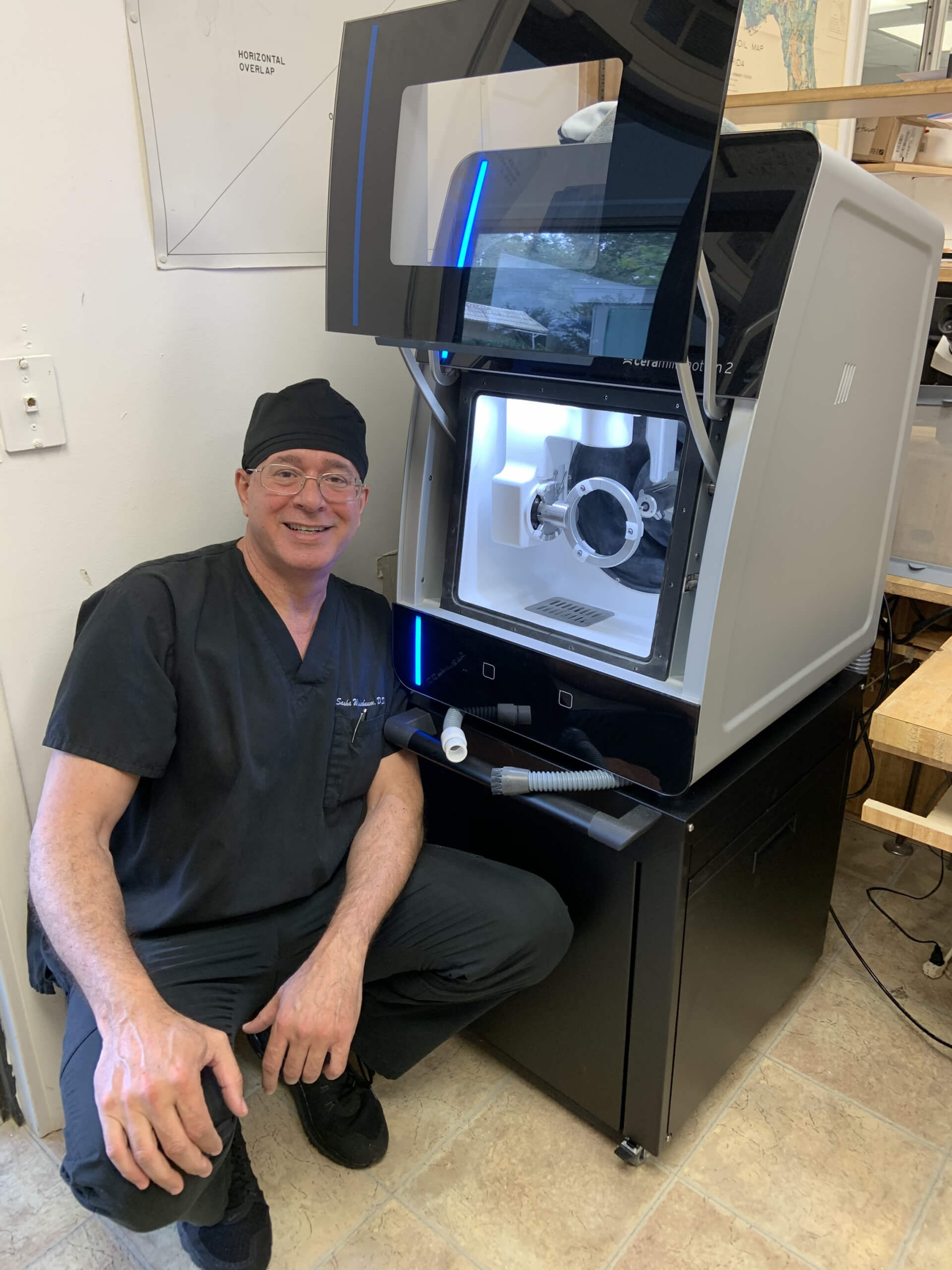

Sasha Winderbaum DDS

Sonia Taveras - Sunny Dental Arts Studio

“As a general dentist doing my own lab work, Opulent has always treated me with respect. This is rare since most lab vendors are not friendly. Besides above and beyond customer service, their deep knowledge of hardware and software eases the stress of breaking into this industry. If you want honest and decent people, go with Opulent”

Brian Anderson - Functional Esthetics Inc.

Match the Best In-House Equipment to the Best Support.

No payments for six months

Error: Contact form not found.